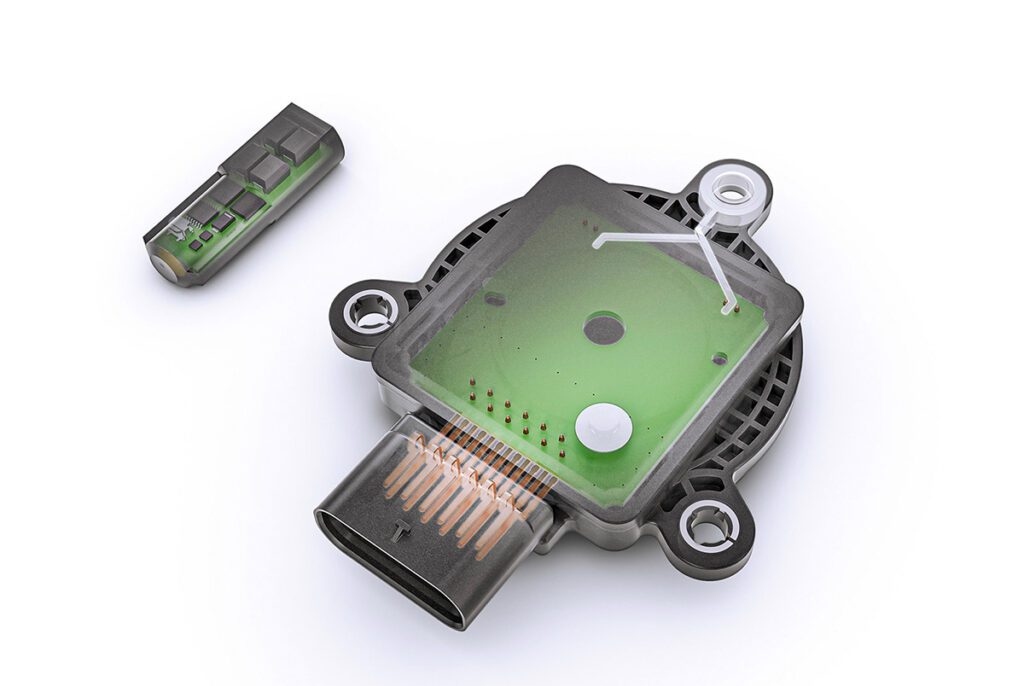

Continental has developed a new sensor technology that measures the temperature inside permanently excited synchronous motors in EVs directly on the rotor. The company says its e-Motor Rotor Temperature Sensor (eRTS) delivers significantly more precise measurement results than the current software-based temperature simulation. This should enable vehicle manufacturers to reduce the amount of rare earth elements used to increase the magnets’ heat resistance.

eRTS contains two separate components: a wireless mote temperature sensor unit located close to the magnet in the EV motor; and a wired transducer element located outside the EV motor. It is connected to the inverter control.

Rotors operate under extreme conditions—sometimes at temperatures of up to 150° C—so monitoring and controlling temperature development in EV motors is crucial. Currently, heat development is not measured directly, but calculated based on information from the stator temperature sensor, phase current measurements and environmental variables. This measurement method has with a tolerance range of up to 15° C. To protect the magnet from demagnetization due to excessive temperature, expensive rare earth elements are used to cover the entire tolerance range and ensure the magnet is heat-resistant. The new eRTS sensor technology allows the tolerance range to be reduced to 3° C. This means that car manufacturers could substantially reduce their usage of costly rare earth materials—or alternatively, improve motor performance by pushing the limits of the tolerance range.

“Our E-Mobility Sensors product center aims to increase efficiency and sustainability in electric vehicles,” says Christoph Busch, head of Continental’s Product Center. “The eRTS technology is a good example of this: reducing the use of rare earths contributes to a more sustainable supply chain. In combination with other sensor technologies, such as the e-Motor Rotor Position Sensor, it can even act as a system solution to create synergies that can save car manufacturers money and effort.”

Source: Continental